What is a wet belt system?

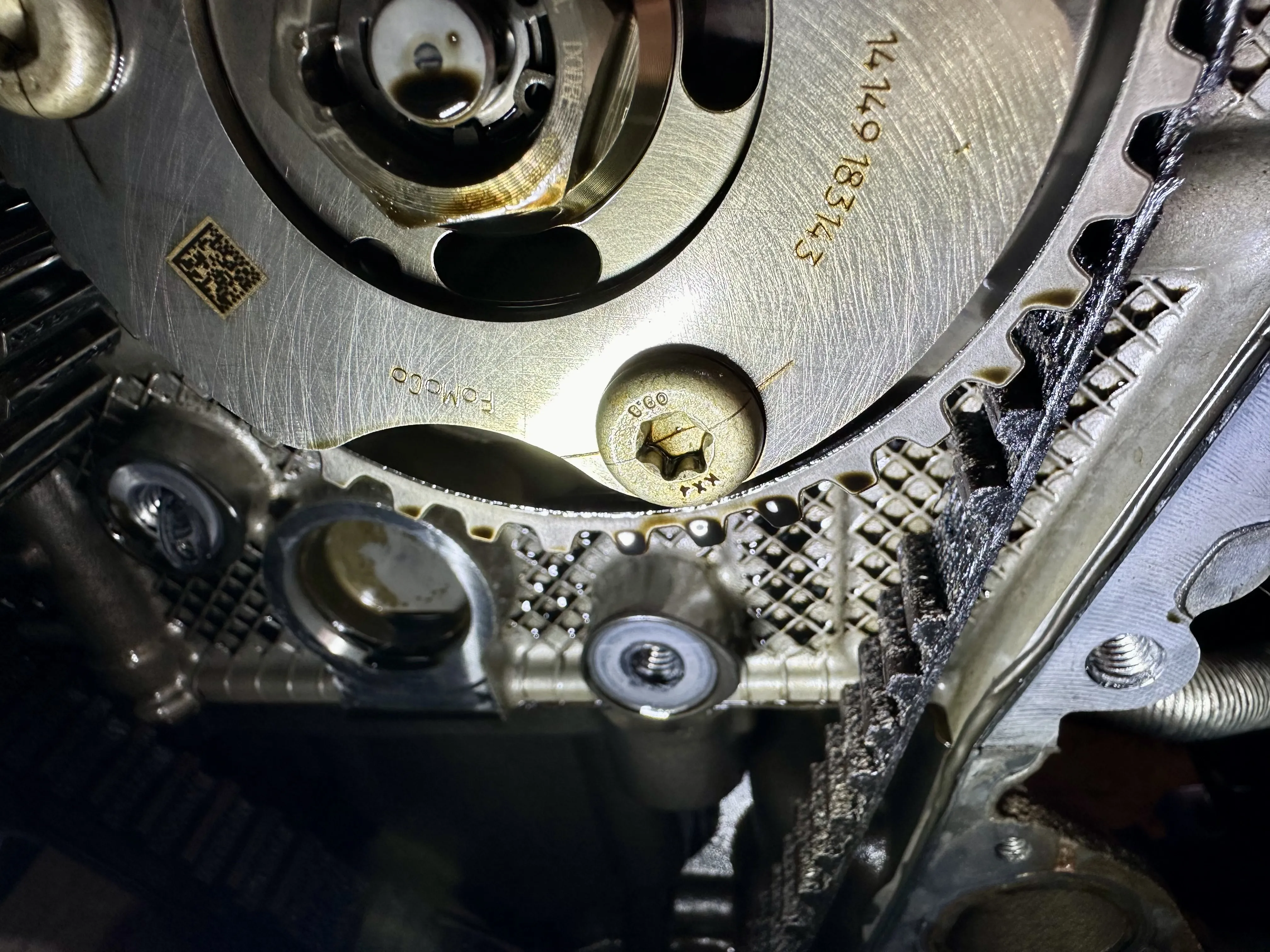

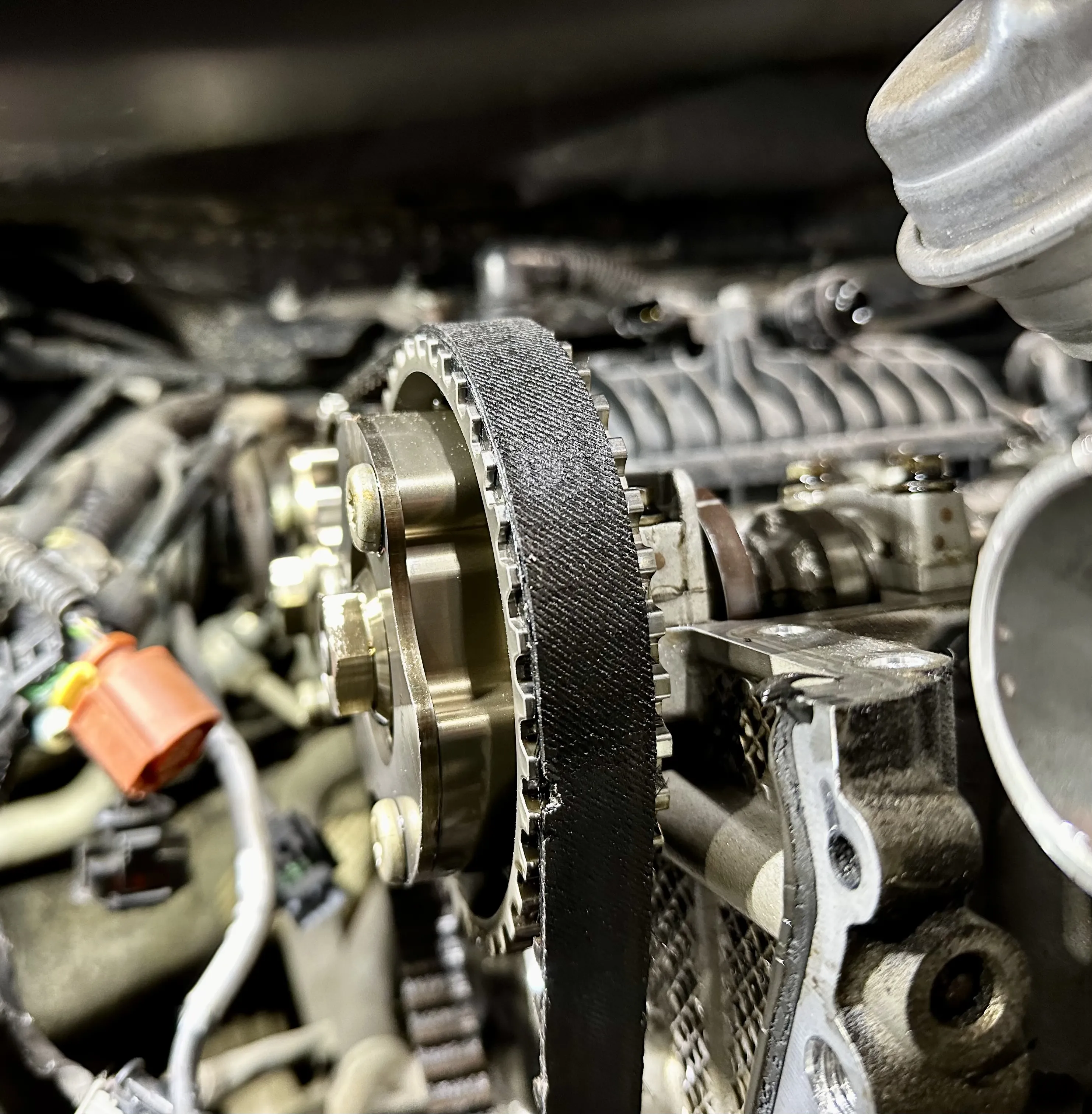

Timing-belt-in-oil (TBIO) or ‘wet belt’ systems that are fully-encased in the engine, were introduced to meet emissions targets, reduce the weight of components and the engine’s overall size, and make it as efficient as possible.

A wet belt system or timing belt in oil (TBIO) is an engine timing belt that operates immersed in engine oil, fully encased in the engine. As opposed to a traditional dry belt which runs outside of the engine’s lubricated areas.

They were introduced to meet emission targets.

By reducing the engine weight, size, internal friction and wear. They were designed to increase efficiency providing better fuel consumption, potentially contributing to improved overall engine performance.

Currently in use by Ford, Volkswagen Group and PSA, wet belt systems are designed to last for up to 10 years.

However, more recently, manufacturers have revised the timing belt change interval to ensure the engine is protected from premature belt failure.

Wet belt problems?

Although wet belt engines offer benefits in terms of efficiency and maintenance intervals, they have had some reliability concerns, particularly in early implementations.

If the engine oil is not maintained properly; low oil level, using incorrect oil or excessive service schedules, contaminants can affect the wet belt, potentially leading to premature wear or failure. Ensuring regular oil changes with the correct oil specification is crucial.

Vehicles running low mileage and short start-stop journeys do not expel the moisture and fuel parts from the crankcase as they rarely reach normal operating temperature. As the oil degrades, acidity increases affecting the properties of the belt.

Wet belt systems can be more complex and expensive to repair or replace compared to dry belts or timing chains. If the wet belt does need to be replaced, it can involve significant labor due to its placement within the engine.

Initial Problems in Certain Models

Some Ford models, particularly certain EcoBoost engines, have experienced issues with wet belts. Early versions of the 1.0L EcoBoost engine, for example, had reports of premature belt degradation, leading to costly repairs. Ford has addressed many of these issues in newer models partly through reducing the period of belt replacement.

Recommendations for Owners

Follow the manufacturers recommended maintenance schedule, especially for oil changes. We recommend 7500-10000 miles or once a year for oil service intervals to ensure the longevity of the wet belt. Using the correct type of oil is critical to avoid contamination and degradation of the belt.

Be aware of any unusual noises from the engine bay, reduced performance, or warning lights on the dashboard, which could indicate a problem with the timing belt system. On some models you might notice a stiffness in the brake pedal. This can be caused by the wet belt degrading and blocking the brake vacuum filter.

Service History

When purchasing a used vehicle with a wet belt engine, check the service history to ensure that proper maintenance has been performed, particularly regarding oil changes.

Consider purchasing an extended warranty if concerned about potential repair costs, especially for higher mileage vehicles or those showing signs of wear.

Conclusion:

Wet belt engines offer benefits in terms of efficiency and maintenance intervals but have had some reliability concerns.

Proper maintenance is essential to ensure the longevity and reliability of these engines. For prospective buyers or current owners, staying informed about specific engine models and their service requirements is key to mitigating potential issues.

Yes, Some manufacturers have updated the maintenance intervals for their wet belt engines, primarily due to issues with premature wear and potential degradation. For the 1.0L EcoBoost engines, the recommended interval has been adjusted from 150,000 miles or 10 years to 100,000 miles or 10 years. Similarly, for the 2.0L EcoBlue engines, the interval has been reduced to 100,000 miles or 6 years due to concerns about oil dilution and the impact on the timing belt’s service life .

These changes aim to enhance the reliability of the engines and prevent failures that could occur if the original intervals were followed. Regular servicing and timely replacement of the wet belts are crucial for maintaining engine health and avoiding costly repairs.

The Wynn’s solution: How engine flush can help maintain your wet belt engine

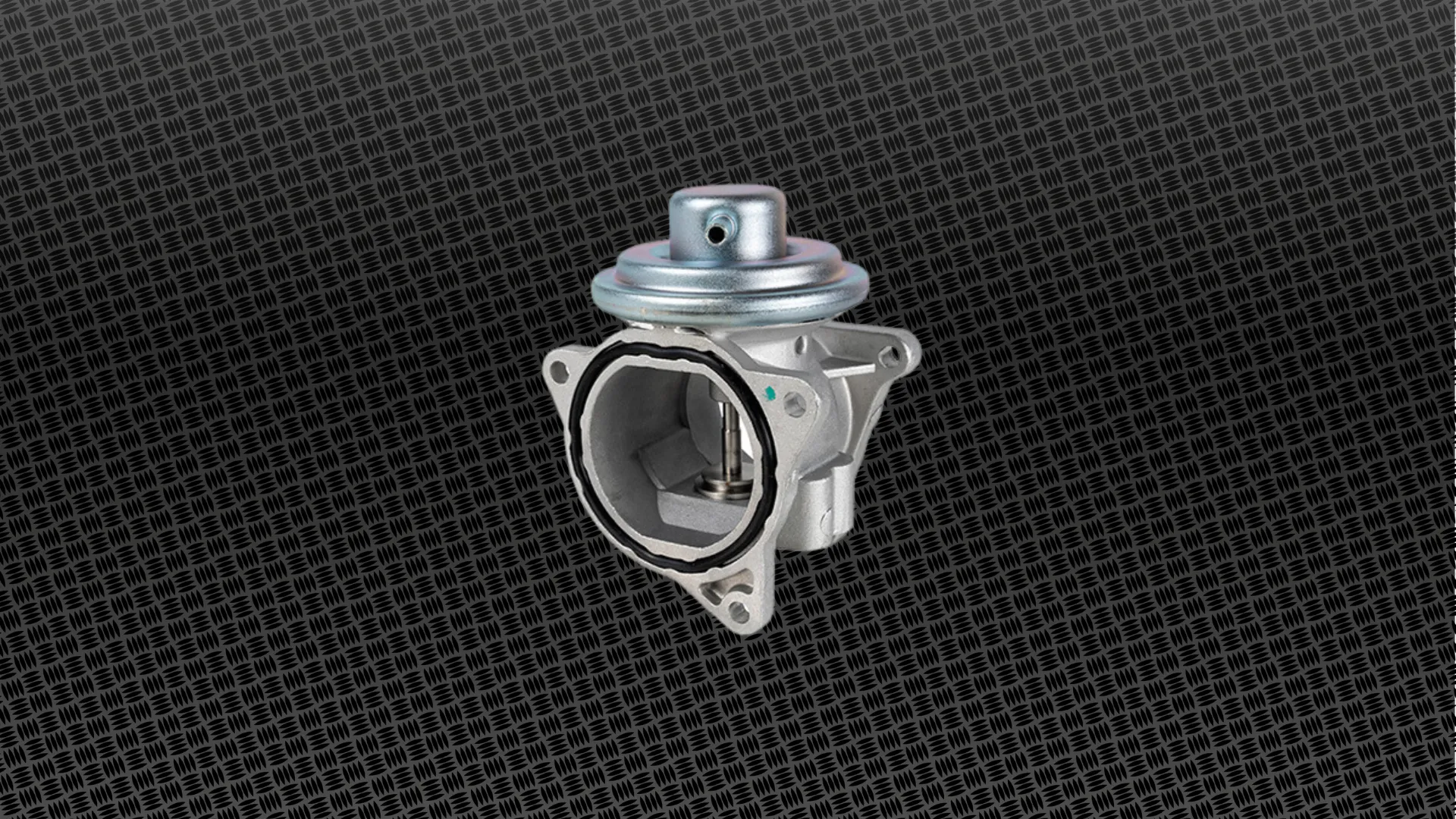

The cleanliness of the oil system is crucial for ensuring proper operation and longevity in all modern engines. As we have seen, wet belt engines needs extra care. This is even more critical when one considers the advent of bio fuels, ethanol, EGR and start stop systems.

Wynn’s oil system cleaner contains detergents and dispersants; the detergents help to remove sludge and varnishes from the engine components, whereas the dispersants keep contaminants suspended in the engine oil and prevent them from agglomerating until the oil is drained.

Clean oil passages ensure that the wet belt and associated components receive proper lubrication, potentially extending their lifespan.

By clearing out contaminants, engine flush can improve engine performance, including smoother operation and potentially better fuel efficiency.

Oil system cleaner also addresses problems of oil dilution by neutralising acidity in the system which can cause wet belts to degrade.

It also addresses the advent of bio diesel, ethanol, EGR and start stop systems which all contribute to the stresses on modern engines.

Information provided by SWL 2025.